All the modules can work independently

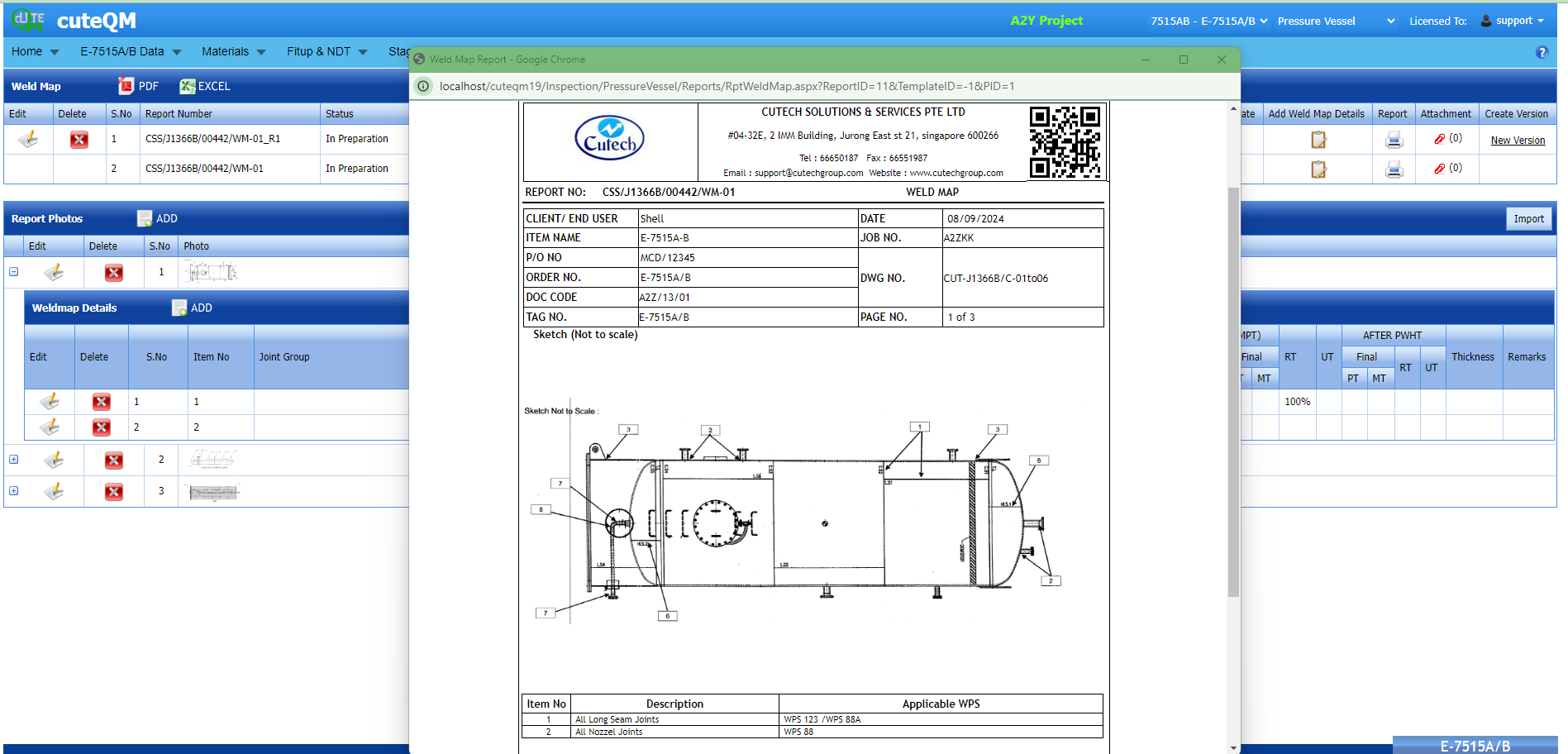

Reports can be generated in different format for different client requirements.

Available in the web and App. The App is supported in Android and iOS for inspections.

cuteQM provides easy to use tools to manage the entire QA / QC operations and improve productivity.

Cute Infocomm has tremendous amount of domain expertise and built the solution.

Headquartered in Singapore, Cute Infocomm’s cuteQM is used by major shipyards, pressure vessel/heat exchanger manufacturers, pipe spool fabricators and skids/modules fabricators around the world.

AI enabled tools makes some of the mundane tasks very much easier to perform in cuteQM.

Reports can be generated in different format for different client requirements.

Available in the web and App. The App is supported in Android and iOS for inspections.

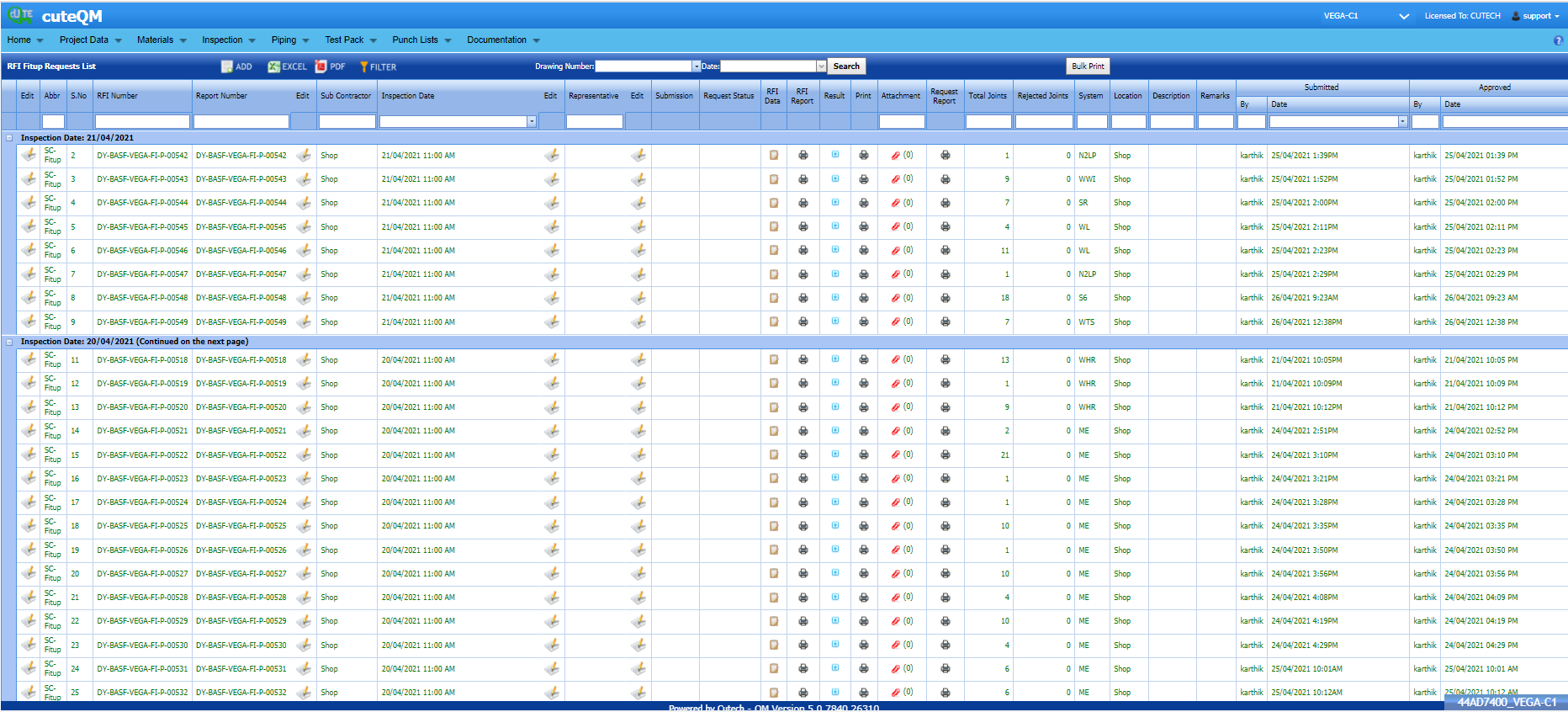

Yes. All the reports, starting from Material Receiving Inspection, Fit-up, Weld-Visual, NDT Request/Reports, Stage Inspections and all the way to Final documentation is streamlined. cuteQM also includes calibration records, welder re-qualification, Material Certificate Maintenance etc.

Yes. Multiple projects at different locations can be run using the system. Also multiple users can work in the system simultaniously and keep the data updates and reports generated.

No. cuteQM is a web based product and hence it will be installed only in your server and all the users can access using web browsers. However, the mobile app requires to be installed in all mobile phones for use.

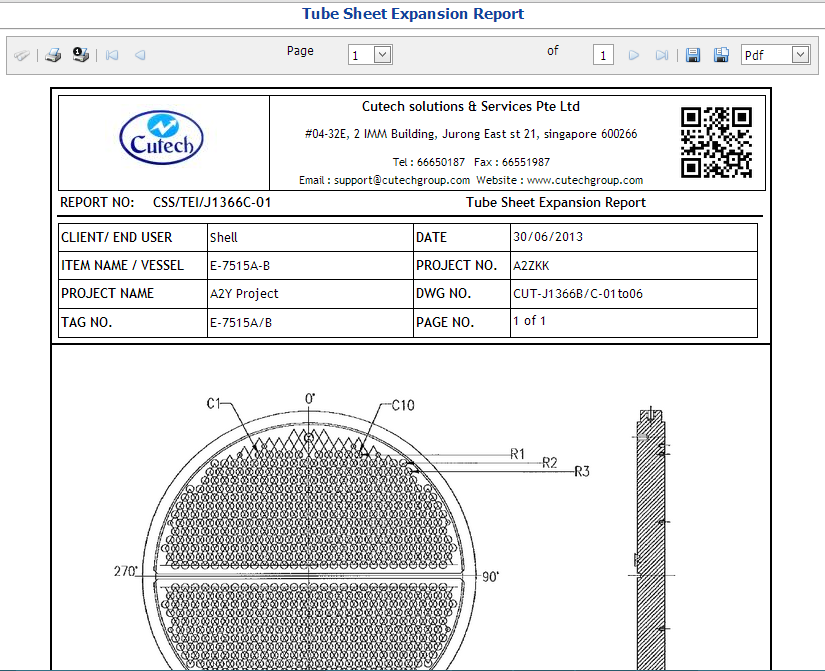

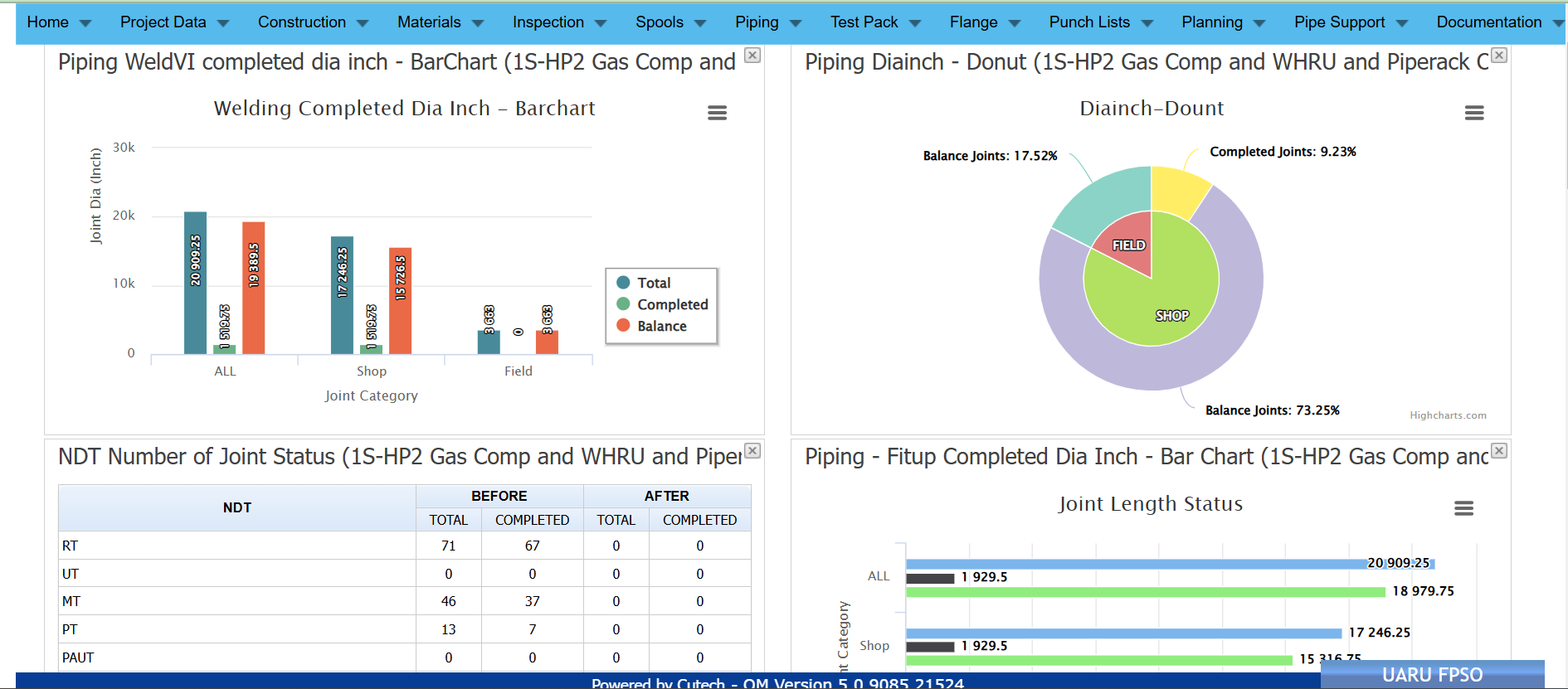

Here are some screenshots from the solution..

cuteQM has the following modules and they all works independently and also tightly integrated with each other where required.

Lines, ISO, Spools, Joints data with fitup, weld visual, NDT, Spool Release, Painting, Test pack etc.

Drawing, Cutting Plan with piece marks, Weld Map Joints data, Process from fitup, weld visual, NDT etc.

Starting from ITP, drawings, Material inspection, fitup, visual, NDT and stage inspections are all handled Here.

Electrical and intrumentation processes starting from equipment installations, cable trays, Mechanical completion checklists.

Help to capture production activities to keep track of time spent to analyse and improve costings.

The compilation of documentation is one of the critical activities. MDR Module helps to combine and generate TOC with appropriate page numberings etc.

Based on the BOM, study the feasibility of constructing the spools by comparing the available material.

The production team and inspectors can use the cuteQM App in Android and iOS devices and perform most activities.

Call us to book an appointment with our consultant to understand the package details more. We can also advise on the government grant SMEGoDigital related details.

Here are some educational videos available on different modules along with brochures.

The QA Produtivity Suite can be applied under EDG for approval for SME clients with upto 50% grant.

The common questions asked by many of the clients are here.

It depends. If the solution is hosted with public IP address it can be accessed. However, if it is hosted inside your private company network then you may need VPN kind of setup to access.

The solution comes with a license for all your employees in your commpany. This means it is unlimited user license. You are free to create any number of users in the system.

Our solution is not a materal control system. However, we do have a material feasibility module whereby the system can analyse which spools can be fabricated based on the material availability.

Yes. cuteQM can provide integration services to automatically pull the material from your material control system and generate the material inward inspection report. With this integration, the matreial inspector needs to check only the heat numbers and certificates without entering the material details data.

Yes. As part of the implementation, we shall add additional reports as required.

Contact us for more details and consultation. We operate 9.00 AM to 6.00 PM

#04-33, Pioneer Junction, 3, Soon Lee Street, Singapore 627606

enquiry@cuteinfocomm.com

+65 6904 2340 / +65 9630 7615